| Availability: | |

|---|---|

| Quantity: | |

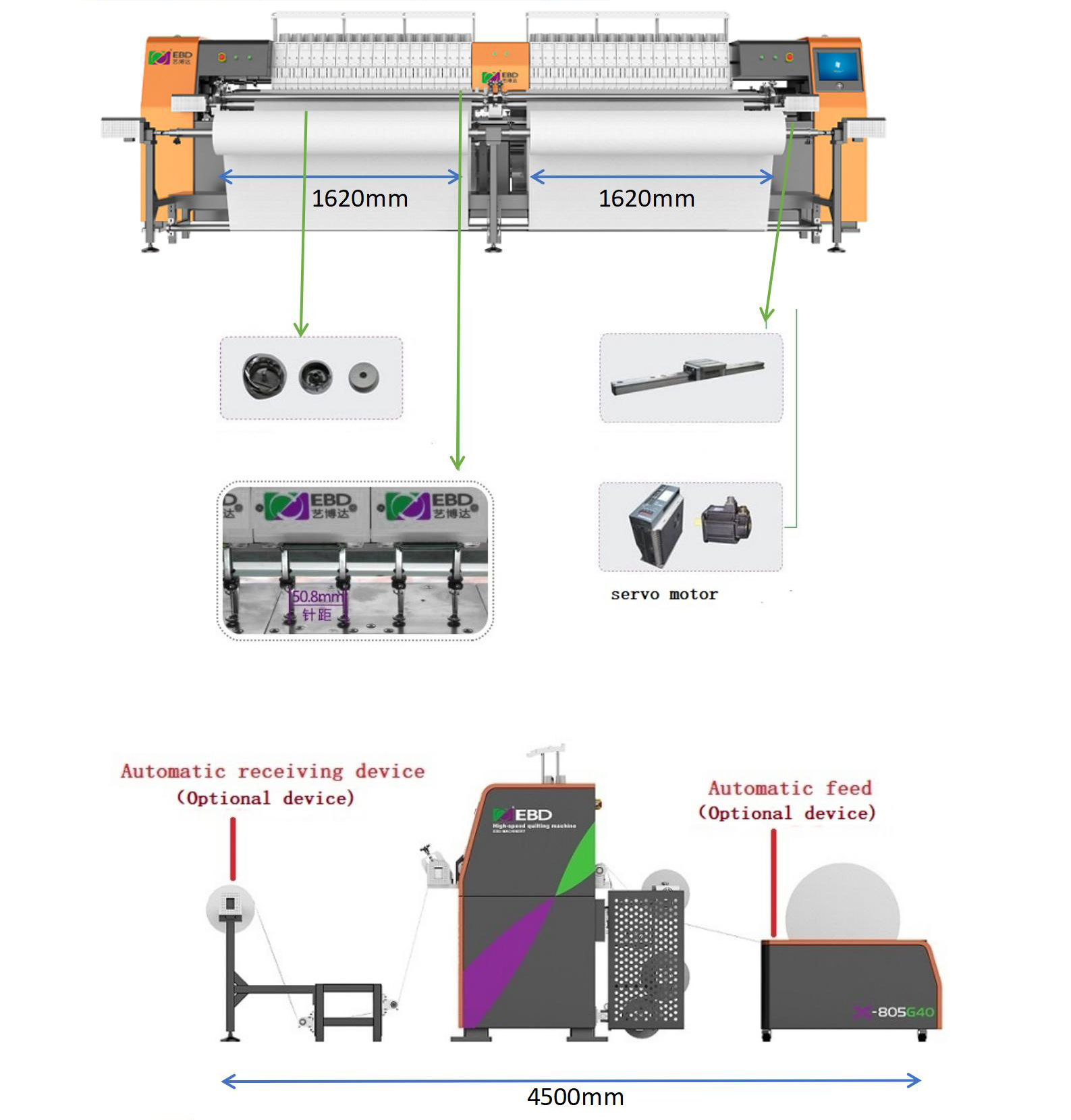

YBD164 (Sectionalized)

yiboda

Specifications/parameters

Specifications/parameters

Product Model | YBD164 | Remarks |

Needle Numbers | 64 needles | |

Needle Gap | 50.8mm | |

Maximum travel in the X-axis direction | 254mm | |

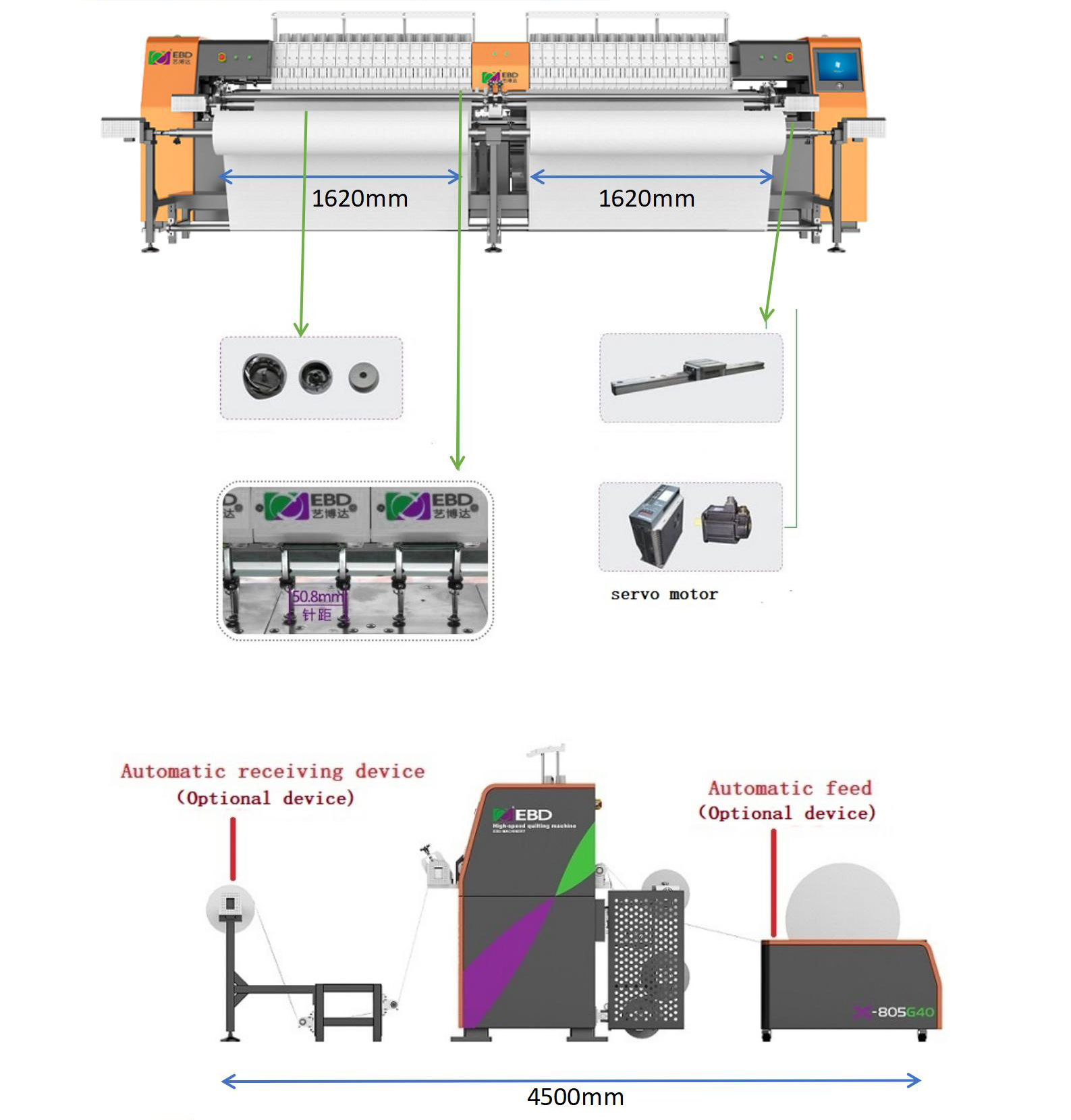

Working Width | 1620*2mm | The working width is the width of machine quilting, but the width of fabric fed |

Stitch Step | 2mm-12mm | |

Speed | 750-1000 R.P.M | |

Needle Size | 12*-18* | |

Voltage | AC220/380V.50Hz | Can customize according to different countries |

Power | 6KW | |

Machine Size | L5600*W1300*H1650(mm) | After removing the feeding bracket: L1156mm, H1567mm |

The needle gaps can be customized to be:67.5mm ,76.2mm. | ||

Features

Features

1. Jumbo rotary hook for the bottom thread reduces a lot of times for changing the bobbins.2. lntegrated structure machine frame makes sure the machine running stably with high speed3. Quilting speed can maintain 1000RPM without decreasing when stitch step is within 5mm,(Yiboda is the pioneerin this field).

4. Synchronized driving structure roller system can guarantee the product quilting precision withoutadjusting the rollers while quiltingthe materials with various thicknesses (Yiboda is thepioneer in this field)

5. Unigue driving structure can guarantee the rollers rolling smoothly and stably during machine running.

6. 10 inches(Can customize 15inches) touch screen control system makes the machine operation easier andsimpler.

7. The screen can read and display the complete patterns, and the patterns can be edited on it (Yiboda isthe pioneer in this field)8. Each page of the operating system is with help function, new operator can operate the machine in ashort time after reading the help pages that saves the staff training time.

9. Intelligent head lock embroidery function is optional.

10.Automatic winding and fabric feeding devices are optional.

Product diagram

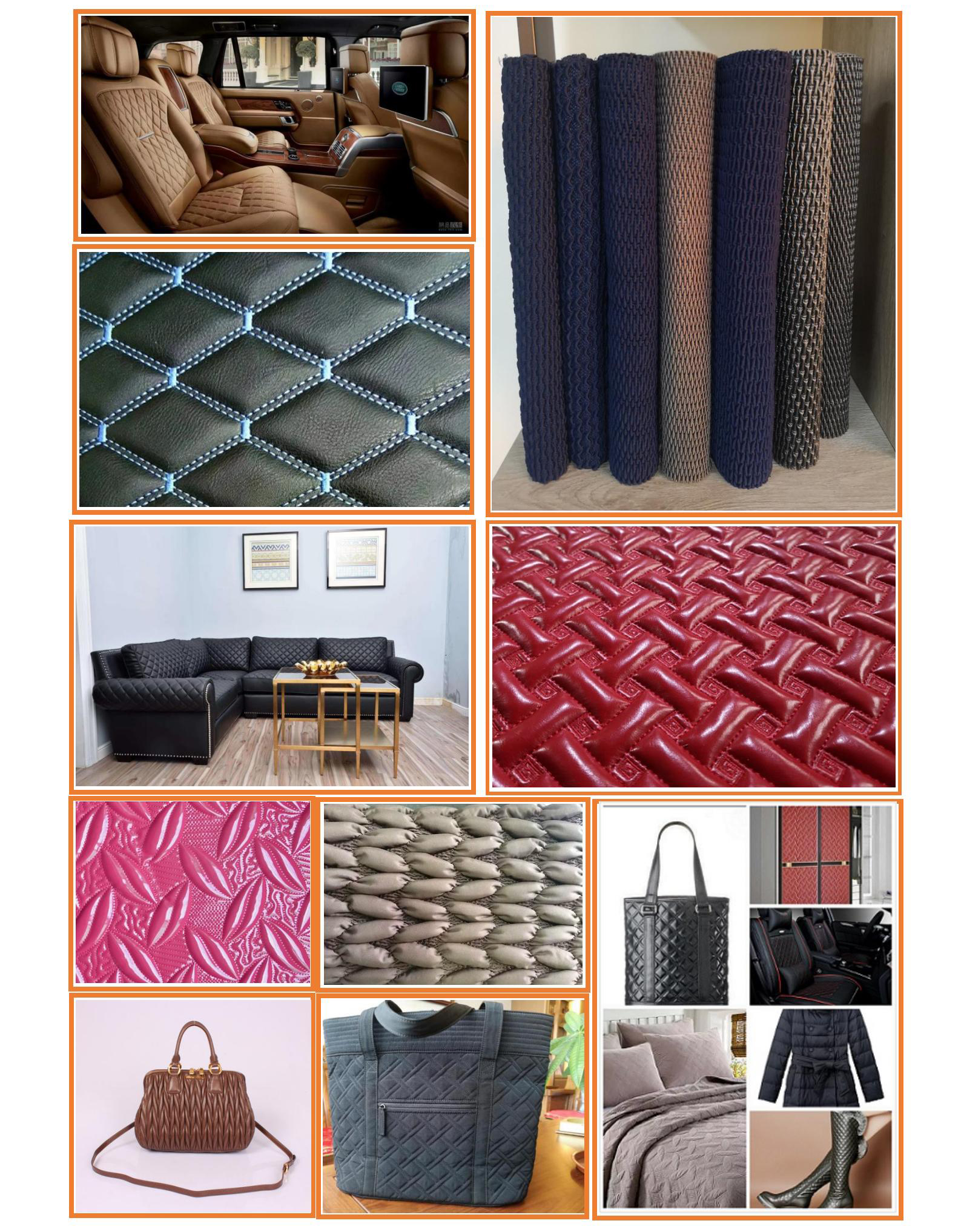

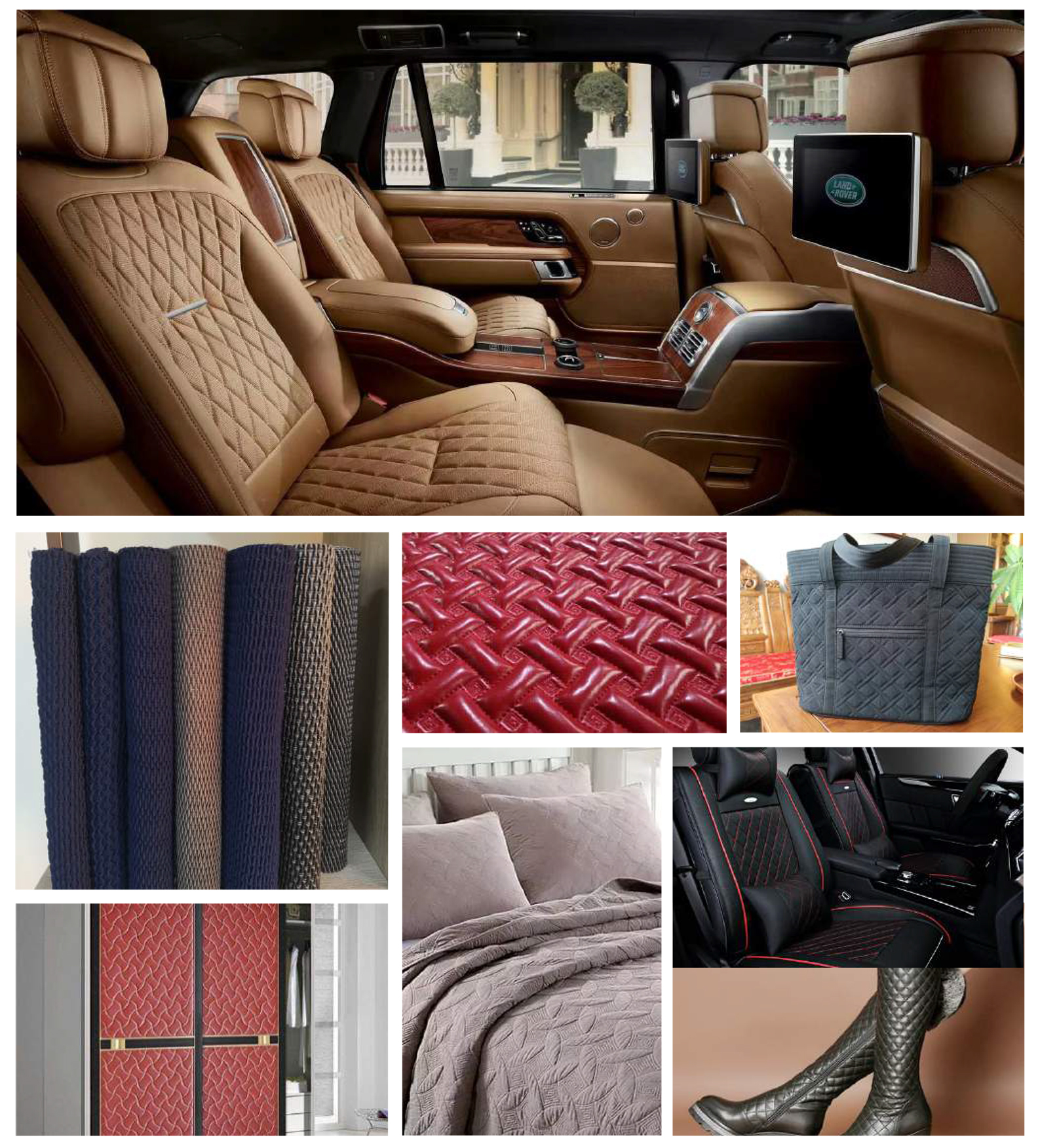

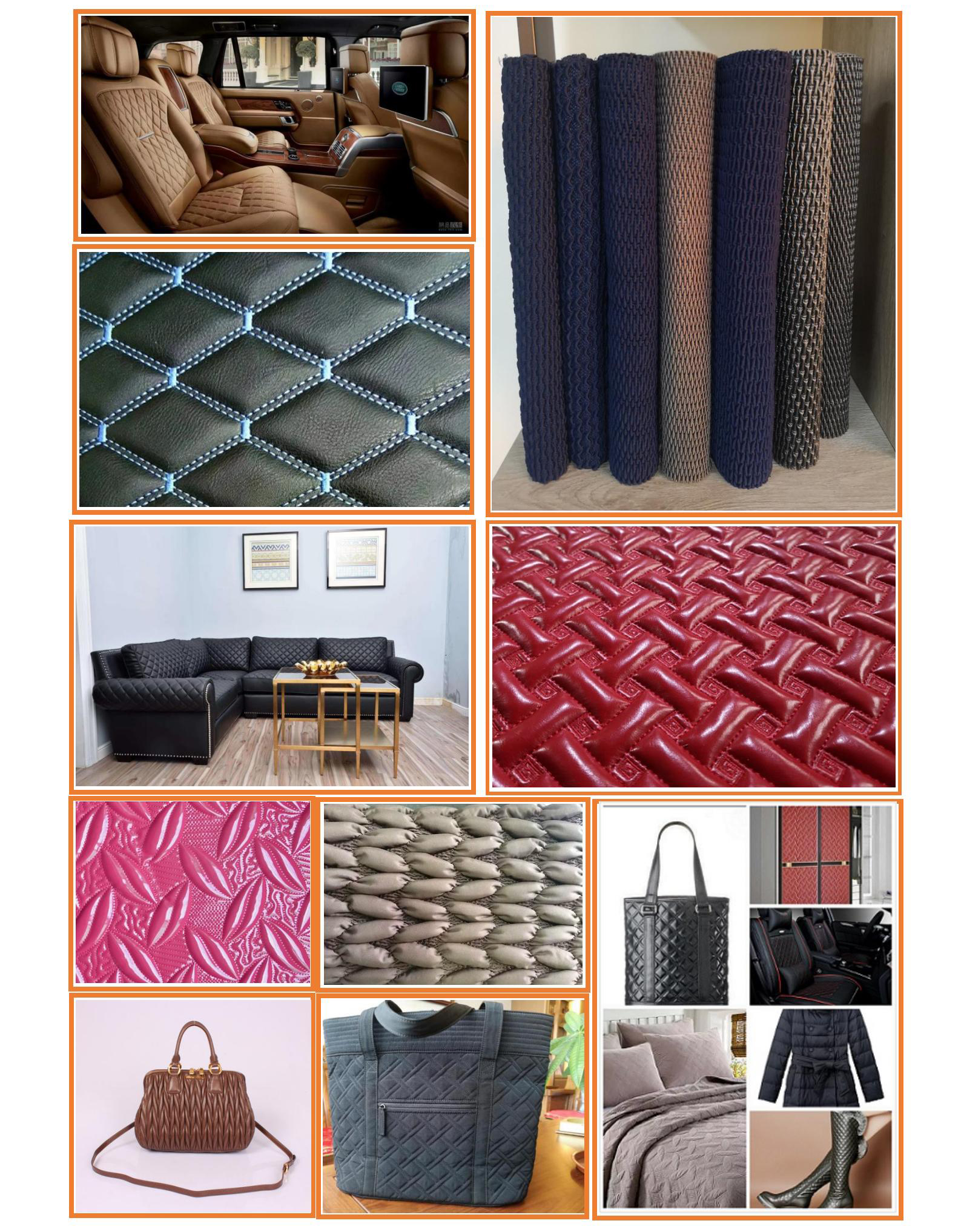

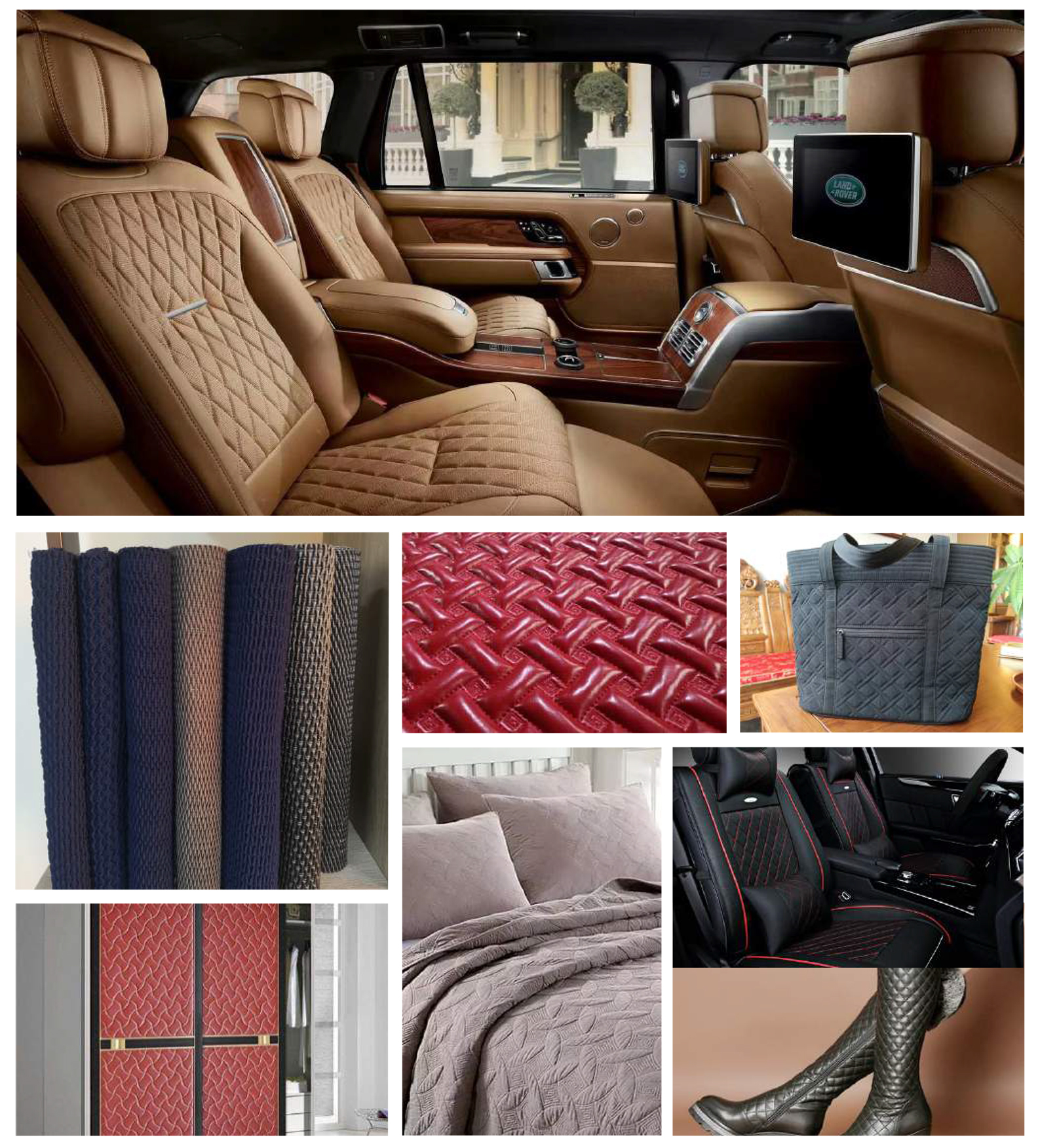

Application Range

Garment, furniture, hand bag, car seat cover, shoes and so on.

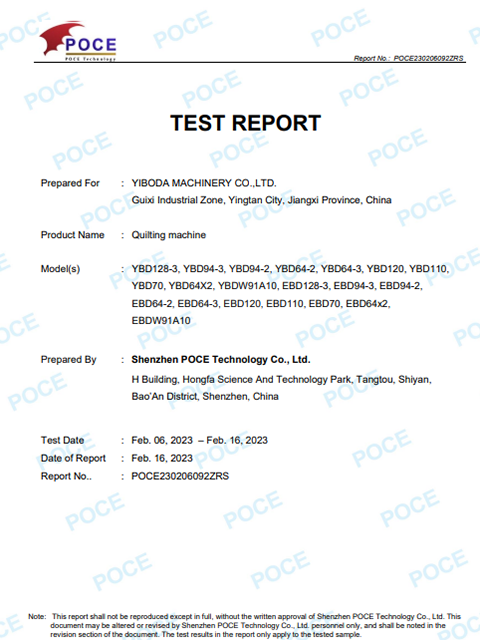

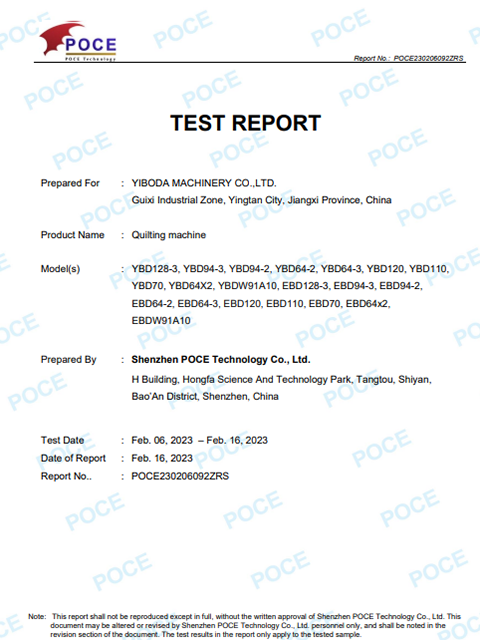

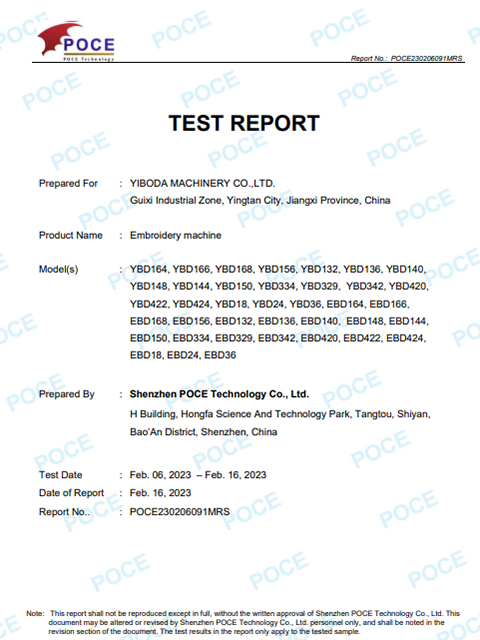

Certifications

|  |  |  |

| Company profile |

yiboda Industrial Co., Ltd. is a modern high-tech enterprise integrating product research and development, production, sales and service. Its leading products are EBD brand series of embroidery machines, quilting machines, computerized quilting embroidery machines, computer multi-needle quilting machines. , rotary hook multi-needle quilting machine, computer embroidery machine, automatic clothing template machine, single needle quilting machine. The company is headquartered in Dongguan, Guangdong Province, the first manufacturing city in China. The production base is located in Yingtan City, Jiangxi Province, China. After years of hard work, development and innovation, the company has established a successful operation and management of the decision-making team and a variety of professional and technical personnel and manufacturing experience, and established a quilting machine, quilting machine, rotary quilting machine and embroidery machine. The design, manufacturing, quality control, and after-sales service are the complete set of perfect systems. With perfect management, leading technology and advanced equipment support, our series of products are characterized by complete functions, stable operation, reliable performance and convenient operation, which are well received by domestic and foreign customers. Companies adhering to the "professional, innovative, development, service" spirit, provide users with comprehensive after-sales service and technical support. Giving timely and thoughtful after-sales service |

|  |  |

|  |  |

Related Products

quilting machine for bed linen from hotel using

Quilting machine for bedding

The factory uses quilted clothing

Professional production of quilting machinery manufacturers

Demonstration of dual-system quilting machine#Quilting machine#Embroidery machine

Clothing quilting machine

Quilting machine customers are used to sew clothing fabrics#Sew a cotton-padded coat

Quilting machine sewing clothing fabric

Sewn Shoe Materials and Fabrics

Chain Embroidery Machine Rotary hook - Multi-needle overlock machine

Yiboda Super Large Rotary Hook Multi-needle Quilting Machine

Multi-needle Rotary Hook Quilting Machine for multi-needle patterns quilting hometextile products

Multi-Needles Shuttle Quilting Machine

Yiboda Computerized Quilting Embroidery Machine

Multi-needle overlock sewing machine

Multi-needle Quilting machine that can meet the high-speed production requirement

Multi-needle overlock sewing machine

Garments jackets making machine shuttle lock stitch multi-needle quilting machine

Computerized Multi Needle Shuttle Quilting Machine Flying Shuttle

Glove processing equipment

automatic perforation embroidery and sewing machine

Specifications/parameters

Specifications/parameters

Product Model | YBD164 | Remarks |

Needle Numbers | 64 needles | |

Needle Gap | 50.8mm | |

Maximum travel in the X-axis direction | 254mm | |

Working Width | 1620*2mm | The working width is the width of machine quilting, but the width of fabric fed |

Stitch Step | 2mm-12mm | |

Speed | 750-1000 R.P.M | |

Needle Size | 12*-18* | |

Voltage | AC220/380V.50Hz | Can customize according to different countries |

Power | 6KW | |

Machine Size | L5600*W1300*H1650(mm) | After removing the feeding bracket: L1156mm, H1567mm |

The needle gaps can be customized to be:67.5mm ,76.2mm. | ||

Features

Features

1. Jumbo rotary hook for the bottom thread reduces a lot of times for changing the bobbins.2. lntegrated structure machine frame makes sure the machine running stably with high speed3. Quilting speed can maintain 1000RPM without decreasing when stitch step is within 5mm,(Yiboda is the pioneerin this field).

4. Synchronized driving structure roller system can guarantee the product quilting precision withoutadjusting the rollers while quiltingthe materials with various thicknesses (Yiboda is thepioneer in this field)

5. Unigue driving structure can guarantee the rollers rolling smoothly and stably during machine running.

6. 10 inches(Can customize 15inches) touch screen control system makes the machine operation easier andsimpler.

7. The screen can read and display the complete patterns, and the patterns can be edited on it (Yiboda isthe pioneer in this field)8. Each page of the operating system is with help function, new operator can operate the machine in ashort time after reading the help pages that saves the staff training time.

9. Intelligent head lock embroidery function is optional.

10.Automatic winding and fabric feeding devices are optional.

Product diagram

Application Range

Garment, furniture, hand bag, car seat cover, shoes and so on.

Certifications

|  |  |  |

| Company profile |

yiboda Industrial Co., Ltd. is a modern high-tech enterprise integrating product research and development, production, sales and service. Its leading products are EBD brand series of embroidery machines, quilting machines, computerized quilting embroidery machines, computer multi-needle quilting machines. , rotary hook multi-needle quilting machine, computer embroidery machine, automatic clothing template machine, single needle quilting machine. The company is headquartered in Dongguan, Guangdong Province, the first manufacturing city in China. The production base is located in Yingtan City, Jiangxi Province, China. After years of hard work, development and innovation, the company has established a successful operation and management of the decision-making team and a variety of professional and technical personnel and manufacturing experience, and established a quilting machine, quilting machine, rotary quilting machine and embroidery machine. The design, manufacturing, quality control, and after-sales service are the complete set of perfect systems. With perfect management, leading technology and advanced equipment support, our series of products are characterized by complete functions, stable operation, reliable performance and convenient operation, which are well received by domestic and foreign customers. Companies adhering to the "professional, innovative, development, service" spirit, provide users with comprehensive after-sales service and technical support. Giving timely and thoughtful after-sales service |

|  |  |

|  |  |

Related Products

quilting machine for bed linen from hotel using

Quilting machine for bedding

The factory uses quilted clothing

Professional production of quilting machinery manufacturers

Demonstration of dual-system quilting machine#Quilting machine#Embroidery machine

Clothing quilting machine

Quilting machine customers are used to sew clothing fabrics#Sew a cotton-padded coat

Quilting machine sewing clothing fabric

Sewn Shoe Materials and Fabrics

Chain Embroidery Machine Rotary hook - Multi-needle overlock machine

Yiboda Super Large Rotary Hook Multi-needle Quilting Machine

Multi-needle Rotary Hook Quilting Machine for multi-needle patterns quilting hometextile products

Multi-Needles Shuttle Quilting Machine

Yiboda Computerized Quilting Embroidery Machine

Multi-needle overlock sewing machine

Multi-needle Quilting machine that can meet the high-speed production requirement

Multi-needle overlock sewing machine

Garments jackets making machine shuttle lock stitch multi-needle quilting machine

Computerized Multi Needle Shuttle Quilting Machine Flying Shuttle

Glove processing equipment

automatic perforation embroidery and sewing machine