Views: 0 Author: Site Editor Publish Time: 2025-11-16 Origin: Site

Are you looking to boost efficiency in your production line? Horizontal quilting embroidery machines might be the answer. These innovative machines combine speed and precision, making them essential for mass production.

In this article, we’ll explore the key benefits of horizontal quilting embroidery machines and how they can enhance quality and reduce costs.

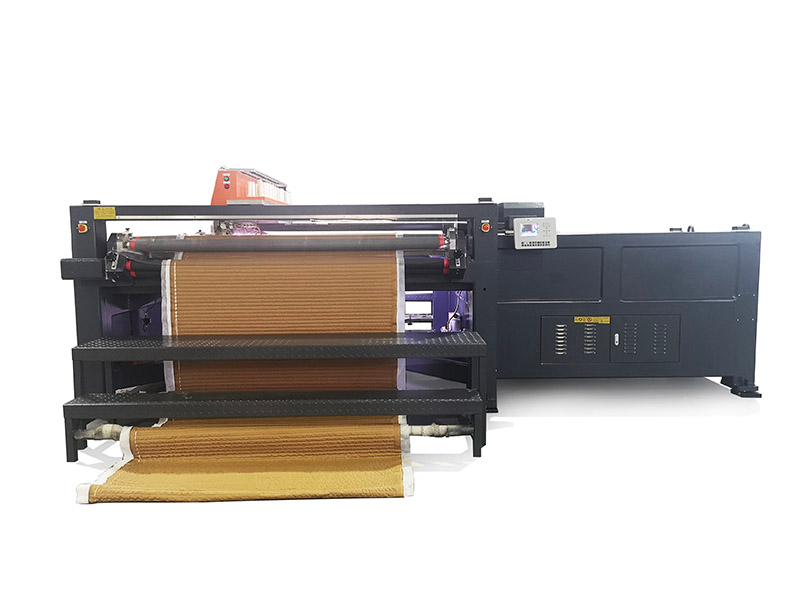

A Horizontal Quilting Embroidery Machine is a specialized device designed for both quilting and embroidery tasks. These machines combine advanced technology to create intricate designs and patterns on various fabrics. They are particularly valued in mass production settings, where efficiency and quality are paramount.

Key Components and Technology Used:

● Sewing Head: The heart of the machine, where the stitching occurs. It often features multiple needles for different thread colors.

● Control Panel: This user-friendly interface allows operators to select patterns, adjust settings, and monitor the machine's performance.

● Fabric Feed System: It ensures smooth movement of the fabric through the machine, which is crucial for maintaining stitch consistency.

● Computerized Systems: Many modern models incorporate digital technology, enabling precise control over designs and stitch patterns.

Cponent | Functionality |

Sewing Head | Executes stitching and embroidery tasks |

Control Panel | Allows user interaction and settings adjustment |

Fabric Feed System | Ensures even fabric movement during operation |

Computerized Systems | Provides digital control for accuracy |

The operational process of a horizontal quilting embroidery machine is quite fascinating. First, the operator selects a design using the control panel. Once the design is chosen, the machine automatically prepares the fabric and threads.

The fabric is then fed into the machine, and the quilting or embroidery begins. As it works, the machine uses precise movements to create the desired patterns. This integration of quilting and embroidery techniques allows for complex designs that would be difficult to achieve manually.

Integration of Quilting and Embroidery Techniques:

● Quilting: The machine layers fabric and batting, stitching them together to create a quilted effect. This is done using various stitch patterns that enhance the texture and appearance.

● Embroidery: Simultaneously, it can apply decorative designs on the surface. The machine's ability to switch between quilting and embroidery without manual intervention saves time and increases productivity.

This combination not only streamlines the production process but also enhances the creative possibilities. By utilizing both techniques in one machine, manufacturers can produce high-quality products more efficiently.

One of the standout features of Horizontal Quilting Embroidery Machines is their enhanced production efficiency. These machines operate at high speeds, achieving up to 850 RPM, while maintaining stable working speeds between 550 to 750 RPM. This capability significantly outpaces traditional manual embroidery methods.

Production Method | Pieces Produced Per Day |

Machine | Hundreds |

Manual | 2-5 |

The comparison is stark: while a machine can produce hundreds of pieces daily, manual methods struggle to keep pace. Additionally, multi-head and multi-needle configurations allow simultaneous processing, further boosting output. For instance, dual-needle independent control enables it to work on different fabric areas at the same time, making it incredibly efficient.

Cost savings are another significant advantage. Horizontal quilting embroidery machines reduce material waste through efficient thread and fabric usage. For example, their large bobbin capacity—often around 120 meters—means operators change threads less frequently, cutting down on waste and downtime.

● Labor Costs: These machines simplify operation, requiring less specialized training. Non-specialized operators can achieve high-quality results, which lowers labor costs.

● Durability and Maintenance: Long-term savings come from the machines' durability and low maintenance needs. Investing in these machines pays off over time, as they withstand heavy use while maintaining performance.

Quality is paramount in mass production, and horizontal quilting embroidery machines excel here. They offer precision stitching and consistent design replication. Digital control systems ensure uniformity, achieving over 98% pattern accuracy.

Quality Metrics | Machine Method | Manual Method |

Error Rate | Low | Higher |

Defect Percentage | Below 2% | Variable |

The advanced stitching technology minimizes defects, making these machines a reliable choice for businesses focused on quality assurance. This level of precision reduces error rates significantly compared to manual methods.

Flexibility is another key benefit. These machines adapt to various fabrics and designs, handling everything from silk to heavy denim. Their versatility extends to different product types, including home textiles, apparel, and even automotive interiors.

● Customization Options: They support various embroidery modes, thread types, and color choices, enabling businesses to meet diverse market demands. This adaptability allows manufacturers to respond quickly to changing trends and customer preferences.

● Material Handling: The ability to work with a wide range of materials makes these machines essential for any production line aiming for versatility.

Overall, horizontal quilting embroidery machines offer numerous advantages, making them indispensable in modern mass production settings.

The Horizontal Quilting Embroidery Machine stands out due to its advanced technology integration, which significantly enhances production capabilities. One of the key innovations is the use of servo motors instead of traditional stepper motors. Servo motors provide better energy efficiency and precision, allowing for smoother operation and reduced power consumption.

● Automation Features: These machines are equipped with automation features like automatic thread cutting and color changing. Such functions minimize downtime and reduce the need for manual intervention, which is crucial in a fast-paced production environment.

Feature | Traditional Motors | Servo Motors |

Energy Efficiency | Lower | Higher |

Precision | Moderate | High |

Setup Time Reduction | Longer | Over 50% Reduction |

Moreover, digital design capabilities allow for quick pattern modifications directly on the machine. This means operators can adjust designs on the fly, cutting setup time by more than 50%. Such flexibility is essential for adapting to changing production needs and customer demands.

When it comes to mass production, the size and scale of the Horizontal Quilting Embroidery Machines play a crucial role. These machines come in various sizes, making them suitable for different production scales. For instance, machine widths range from 1.5 meters to 3.2 meters, accommodating large products effectively.

● Benefits of Larger Quilting Widths: Larger widths are particularly advantageous for oversized products, eliminating the need for fabric piecing. This not only streamlines the production process but also enhances the integrity of the final product.

Machine Width | Suitable Product Types |

1.5 meters | Small textiles |

2.5 meters | Standard quilts |

3.2 meters | Oversized products |

By choosing the right machine size, manufacturers can optimize their production lines, ensuring they meet both quality and efficiency standards. The ability to handle larger items without piecing fabrics together significantly reduces the risk of defects and improves overall product quality.

In summary, these technical features make horizontal quilting embroidery machines indispensable for businesses focused on mass production, combining efficiency, precision, and adaptability to meet market demands.

The Horizontal Quilting Embroidery Machine has become a cornerstone in the home textiles industry. It produces a variety of products, including quilts, bedspreads, and curtains. These machines allow manufacturers to create intricate designs and patterns that appeal to consumers looking for unique home décor items.

● Market Trends: Recently, the demand for personalized and custom home textiles has surged. Consumers are increasingly seeking products that reflect their individual styles, driving manufacturers to invest in advanced embroidery technologies.

Product Type | Key Features | Market Demand |

Quilts | Custom designs, warmth | High |

Bedspreads | Variety of fabrics | Growing |

Curtains | Unique patterns | Increasing |

As trends shift towards sustainability and eco-friendly materials, the ability of these machines to work with various fabrics, including organic cotton and recycled materials, makes them even more valuable.

In the fashion and apparel sector, the Horizontal Quilting Embroidery Machine plays a vital role in custom embroidery for clothing lines. Designers use these machines to add intricate details to garments, enhancing their overall appeal.

● Fast Fashion Integration: The rise of fast fashion has changed how clothing is produced, creating a demand for rapid design changes. These machines enable quick turnarounds, allowing brands to respond swiftly to changing trends and consumer preferences.

Application | Benefits | Industry Impact |

Custom Embroidery | Unique branding | Increased sales |

Rapid Design Changes | Quick production cycles | Competitive advantage |

This flexibility is crucial for brands aiming to stay relevant in a fast-paced market, as it allows them to introduce new collections frequently without compromising quality.

The automotive and upholstery industries also benefit from the capabilities of Horizontal Quilting Embroidery Machines. These machines are used in applications such as car interiors and furniture upholstery, where both durability and aesthetics are paramount.

● Durability and Aesthetics: In automotive upholstery, the materials used must withstand wear and tear while maintaining an attractive appearance. The precision stitching provided by these machines ensures that upholstery not only looks good but also lasts longer.

Application | Key Considerations | Benefits |

Car Interiors | Durability, style | Enhanced customer satisfaction |

Furniture Upholstery | Comfort, design | Higher market value |

By integrating advanced embroidery techniques, manufacturers can create products that meet the rigorous standards of both style and functionality, appealing to consumers who value quality in their automotive and home furnishings.

The Horizontal Quilting Embroidery Machine is increasingly recognized for its role in promoting eco-friendly practices within the textile industry. Manufacturers are now focusing on using sustainable materials and processes that minimize environmental impact. These machines can work efficiently with eco-friendly materials, such as water-soluble backing and silicone-free lubricants, which are essential for reducing harmful emissions during production.

● Energy Efficiency: Modern machines are designed to be energy-efficient, utilizing advanced technology to lower energy consumption. For instance, servo motor systems can provide up to 40% energy savings compared to traditional motors. This significant reduction not only cuts costs for manufacturers but also lessens their carbon footprint.

Feature | Traditional Motors | Servo Motors |

Energy Efficiency | Lower | Up to 40% savings |

Operation Smoothness | Moderate | High |

Maintenance Frequency | Higher | Lower |

This shift towards energy-efficient machinery aligns well with the growing consumer demand for sustainable practices, as more people are looking for products that are both high-quality and environmentally responsible.

In addition to eco-friendly practices, compliance with industry standards is crucial for manufacturers using Horizontal Quilting Embroidery Machines. Certifications such as the Global Organic Textile Standard (GOTS) ensure that products meet stringent environmental and social criteria throughout the production process.

● Importance of Certifications: Meeting these certifications is essential for businesses aiming to market their products as sustainable. It demonstrates a commitment to environmental responsibility, which is increasingly valued by consumers.

Certification | Key Focus | Benefits |

GOTS | Organic materials | Market credibility |

OEKO-TEX | Harmful substances | Consumer safety |

By adhering to these standards, manufacturers can not only enhance their brand reputation but also contribute to a more sustainable future in textile production. Staying compliant with environmental regulations is not just a legal obligation; it’s a pathway to innovation and responsibility in a rapidly evolving market.

In summary, Horizontal Quilting Embroidery Machines offer numerous benefits for mass production. They enhance efficiency, improve product quality, and support eco-friendly practices. Manufacturers should consider these machines to stay competitive in the market.

We encourage businesses to explore investment options in horizontal quilting embroidery technology. Embracing this innovation can lead to significant advantages in production and sustainability.

A: The average cost varies widely, typically ranging from $10,000 to $50,000, depending on features.

A: Consider factors like production volume, types of fabrics, and desired features to meet your specific needs.

A: Yes, these machines are designed for high efficiency and can easily manage large-scale production demands.

A: Regular cleaning, lubrication, and timely servicing are essential for optimal performance and longevity.

A: Yes, many manufacturers offer training programs, manuals, and online resources to help users get started.