Views: 0 Author: Site Editor Publish Time: 2025-11-15 Origin: Site

Are you looking to enhance your production speed? An Industrial Quilting Embroidery Machine might be the answer. These machines play a crucial role in industries like textiles and fashion, significantly boosting efficiency.

In this post, we’ll explore how these machines improve productivity and reduce costs, making them essential for modern manufacturing.

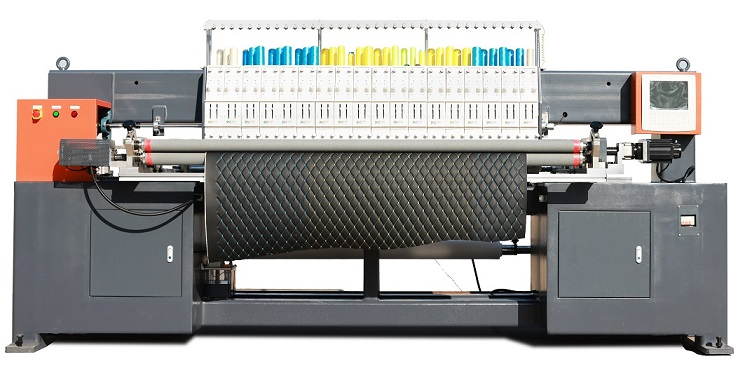

One of the standout features of an Industrial Quilting Embroidery Machine is its multi-head design. This setup allows multiple embroidery heads to operate simultaneously, significantly increasing production capacity. For example, a machine with four heads can complete four designs at once, saving valuable time.

The benefits of having multiple needles are also substantial. Each needle can be threaded with a different color, enabling complex designs to be created without needing to stop and change threads. This not only speeds up the process but also enhances creativity, allowing for intricate patterns that would be time-consuming to achieve with single-needle machines.

These features directly contribute to higher output rates. With the ability to produce more items in less time, businesses can meet customer demands more efficiently, leading to increased profitability.

Industrial machines are designed for high-speed operation, typically ranging from 800 to 1,200 stitches per minute. This is a stark contrast to traditional machines, which often operate at much lower speeds. The speed advantage means that businesses can complete large orders quickly, which is essential in today’s fast-paced market.

Moreover, high-speed operation reduces production timelines significantly. For instance, a project that might take several days with a traditional machine can often be completed in just a few hours. This efficiency is crucial for meeting tight deadlines and maintaining competitive pricing.

Digital control technology is another key feature of modern industrial quilting embroidery machines. These systems offer precise pattern management, allowing operators to easily adjust designs and settings. This flexibility enables quick changes to be made, accommodating last-minute customer requests or design alterations.

Additionally, digital systems help reduce setup time and errors. With automated threading and built-in diagnostics, operators can spend less time on manual adjustments and troubleshooting. This streamlining of processes not only improves efficiency but also enhances the overall quality of the finished product.

Feature | Benefits |

Multi-Head Configuration | Increased production capacity |

Multi-Needle Capability | Faster design changes and color variety |

High-Speed Operation | Reduced production timelines |

Digital Control Systems | Precise adjustments and reduced errors |

These advanced features collectively make Industrial Quilting Embroidery Machines an invaluable asset for businesses looking to boost efficiency in their production processes.

The hardware design of Industrial Quilting Embroidery Machines is crucial for maximizing speed, capacity, and stability. Features like large capacity bobbins significantly reduce the frequency of line changes. For instance, a machine equipped with larger bobbins can operate longer before needing a refill, allowing for continuous production runs without interruptions.

In addition to bobbins, high-strength structures play a vital role. Machines built from robust materials ensure stability during high-speed operations, preventing vibrations or misalignments that could lead to errors. A well-designed machine minimizes downtime, which is essential for maintaining high efficiency. Recent case studies show that factories using optimized hardware design have seen efficiency improvements of up to 30%.

Intelligent control systems revolutionize how these machines operate by automating many manual processes. Automation reduces the need for constant human intervention, allowing operators to focus on more critical tasks. Key features include real-time monitoring and error detection, which enhance operational reliability.

For example, automatic thread break detection systems alert operators when an issue arises and can even resume work automatically. This capability minimizes downtime and keeps production flowing smoothly. Moreover, data tracking and remote diagnostics allow for continual performance monitoring. By diagnosing issues remotely, technicians can resolve problems quickly, further reducing downtime and associated costs.

Feature | Benefits |

Real-Time Monitoring | Enhances operational reliability |

Automatic Thread Break Detection | Minimizes downtime and resumes work quickly |

Remote Diagnostics | Reduces the need for onsite troubleshooting |

Automation is at the heart of modern Industrial Quilting Embroidery Machines. Processes like automatic threading and cutting streamline production, making it more efficient. Integrated workflows allow for large-scale production without bottlenecks.

Continuous feeding systems are particularly beneficial, as they enable uninterrupted production runs, especially for larger products. Additionally, full automation of workflows means functions like feeding, quilting, and cutting can be integrated into one seamless process. This integration reduces the need for multiple operators, leading to lower labor costs and improved production accuracy.

By minimizing manual oversight, automation not only enhances efficiency but also allows for better resource allocation. Workers can focus on quality control and other value-added tasks, ensuring that the final products meet high standards.

One of the primary advantages of Industrial Quilting Embroidery Machines is their cost efficiency. By significantly increasing productivity, these machines enable manufacturers to save on labor costs and materials. For example, a machine that operates at high speed can complete more items in a shorter time, leading to higher output without a proportional increase in expenses.

When analyzing long-term financial benefits, it becomes clear that the initial investment in these machines pays off quickly. While the upfront cost might be substantial, the operational savings gained from reduced labor and increased production capacity often outweigh this expense. A detailed comparison shows that businesses can see a return on investment within a couple of years due to these operational efficiencies.

Cost Aspect | Initial Investment | Operational Savings |

Labor Costs | Moderate | Significant reduction |

Material Waste | Higher | Lower due to precision |

Production Time | Longer | Shorter, more efficient runs |

Maintaining consistent quality is another critical benefit of using Industrial Quilting Embroidery Machines. These machines are designed to reduce defects and minimize rework rates. With advanced features like servo motors and digital controls, they achieve remarkable precision and accuracy. This high level of precision ensures that each product meets stringent quality standards, which is vital for customer satisfaction.

Quality control directly impacts brand reputation. A company known for high-quality products can build strong customer loyalty, which ultimately drives sales. By investing in these machines, manufacturers can enhance their quality assurance processes, leading to fewer returns and increased customer trust.

Industrial Quilting Embroidery Machines offer remarkable flexibility and adaptability. They can handle various materials and designs, making them ideal for businesses with diverse product lines. Whether it’s lightweight fabrics or heavier textiles, these machines can easily switch between different materials, accommodating unique customer needs.

For instance, a case study involving a textile manufacturer demonstrated how quickly they adapted their production line to meet changing market demands. By utilizing the custom design capabilities of their embroidery machines, they could switch between patterns seamlessly, catering to seasonal trends without significant downtime. This adaptability not only keeps production flowing but also helps businesses stay competitive in a fast-paced market.

Feature | Benefits |

Material Handling | Versatile for different fabric types |

Custom Design Capabilities | Quick switching between patterns |

Adaptability | Meeting unique customer demands efficiently |

These specific benefits highlight why Industrial Quilting Embroidery Machines are essential for manufacturers looking to enhance efficiency and maintain a competitive edge.

When considering an Industrial Quilting Embroidery Machine, it's essential to understand the initial investment and ongoing maintenance costs. Purchasing these machines can require a significant upfront expenditure, which varies based on their features and capabilities. Beyond the purchase price, businesses must also factor in maintenance costs, which can include routine servicing, parts replacement, and software updates.

A thorough discussion on return on investment (ROI) reveals that while the initial costs may seem daunting, the long-term savings can be substantial. Increased productivity and reduced labor costs often lead to quicker payback periods. To ensure you're making a wise investment, consider these tips for selecting the right machine based on your business needs:

● Assess Production Volume: Choose a machine that matches your expected output.

● Evaluate Features: Look for features that enhance efficiency, like automatic threading or large capacity bobbins.

● Consider Future Growth: Select a model that can adapt to changing production demands.

Cost Aspect | Initial Investment | Ongoing Maintenance |

Purchase Price | High | Moderate to High |

Parts Replacement | Not applicable initially | Regularly needed |

Software Updates | Included initially | Periodic updates required |

Maximizing the efficiency of an Industrial Quilting Embroidery Machine heavily relies on operator training. Employees need to understand how to operate the machines effectively to avoid costly mistakes and downtime. Training should cover everything from basic operation to troubleshooting common issues.

Fortunately, there are numerous resources available for training employees on new technology. Manufacturers often provide training programs, and many online platforms offer courses tailored to specific machine models. Additionally, investing in continuous learning is vital as the industry evolves. Keeping staff updated on the latest technologies and techniques ensures they can adapt quickly to changes, enhancing overall productivity.

Consider implementing a structured training program that includes:

● Hands-On Workshops: Allow operators to practice on the machines.

● Online Training Modules: Offer flexibility for staff to learn at their own pace.

● Regular Refresher Courses: Keep skills sharp and knowledge current.

Training Aspect | Importance |

Hands-On Experience | Builds confidence and competence |

Online Resources | Provides flexible learning options |

Continuous Learning | Keeps skills relevant in a changing market |

By addressing these challenges and considerations, businesses can better prepare for the successful integration of Industrial Quilting Embroidery Machines into their operations.

Industrial Quilting Embroidery Machines significantly boost efficiency in manufacturing. They enhance productivity, reduce costs, and maintain high-quality standards. Key points include the importance of initial investment and ongoing maintenance, as well as the need for proper training. Investing in these advanced machines is crucial for gaining a competitive edge in today’s market. Embracing technology not only improves operations but also meets customer demands more effectively.

A: Industrial machines are built for high volume and speed, while domestic machines are designed for smaller projects and versatility.

A: Assess production volume, required features, and future growth to select a machine that meets your specific needs.

A: Regular servicing, parts replacement, and software updates are essential for maintaining optimal performance.

A: Yes, these machines can easily accommodate custom designs, enhancing flexibility in production.

A: Industries like textiles, fashion, and home furnishings benefit significantly from increased efficiency and quality.