Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

In today’s fast-moving textile industry, efficiency is key. A major decision is whether to invest in separate machines for quilting and embroidery or a combined machine.

This article explains why a combined industrial quilting and embroidery machine is a smart investment. It helps optimize productivity, cut costs, and expand product options.

If you’re upgrading, Yiboda offers high-performance machines to consider. Learn more about our products today.

Quilting and embroidery, while both involving intricate needlework, serve different purposes. Quilting primarily involves joining three layers of fabric—the quilt top, batting, and backing—using strong, durable stitches to create a cohesive and functional piece. In contrast, embroidery is the process of embellishing fabric with decorative stitching, usually involving a finer thread to add intricate patterns, logos, or designs.

Each of these processes typically requires specialized machines. Quilting machines are built to handle multiple fabric layers, offering precision and strength. Embroidery machines, however, focus on detail, allowing for intricate designs on relatively thinner fabrics.

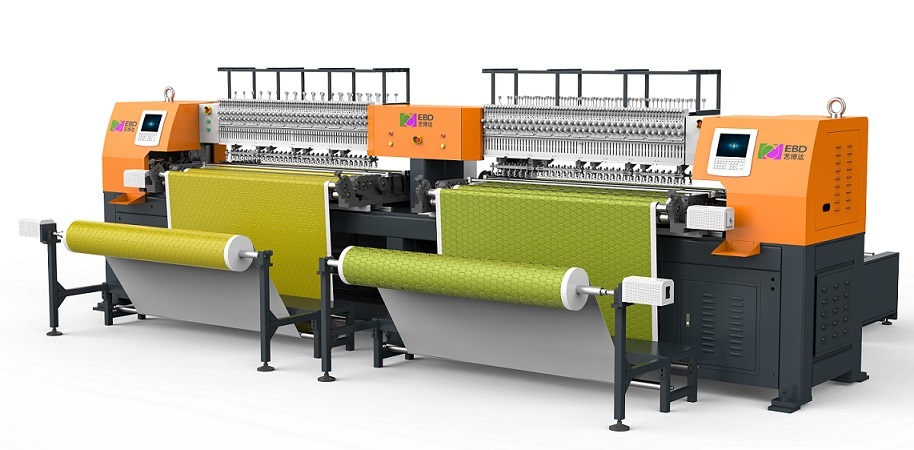

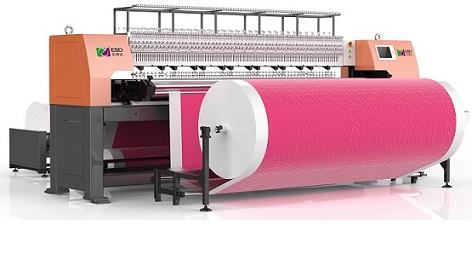

Quilting machines are designed for larger, bulkier projects. They provide the workspace and speed necessary for quilting quilts, bedspreads, or other large items efficiently. In contrast, embroidery machines prioritize detail, offering finer control for creating patterns, logos, and designs on fabric. Combined machines bridge this gap, allowing manufacturers to switch between quilting and embroidery with ease, making them versatile tools that reduce downtime and improve productivity.

Operating separate quilting and embroidery machines can be inefficient for businesses, particularly in fast-paced environments. The time required to set up and switch between machines can slow down production. Additionally, maintaining two machines increases costs related to repairs, training, and floor space. A combined industrial machine offers the solution by reducing these operational inefficiencies.

Combining quilting and embroidery into one machine allows businesses to streamline their production process. Switching between tasks, such as moving from quilting to adding embroidery designs, is done much faster. This integration also reduces the risk of mistakes due to multiple setups and ensures consistent quality across different stages of production.

For example, some modern combined machines are equipped with larger embroidery areas and multiple needle options, making it easier to handle a variety of fabrics and designs. This enhanced versatility is especially beneficial when working on large projects, as manufacturers can complete both quilting and embroidery without interrupting the workflow.

With the ability to quilt and embroider on a single machine, businesses can offer a wider range of products. This flexibility enables manufacturers to produce unique custom items, such as embroidered quilts or personalized home décor. Whether it’s a custom quilt for a client or a large-scale embroidered product for retail, a combined machine can handle a variety of tasks, expanding the creative possibilities for businesses.

From a financial perspective, investing in a combined industrial quilting and embroidery machine can be significantly more cost-effective than purchasing and maintaining two separate machines. The upfront cost may be higher, but the savings in maintenance, space, and the need for only one operator result in reduced overhead in the long term. Combined machines also typically offer more energy-efficient designs, cutting down on electricity costs compared to operating two machines.

Additionally, businesses no longer need to worry about downtime due to machine transitions. With a combined machine, the transition between tasks is seamless, helping businesses increase their production capacity while minimizing the need for multiple staff members or technicians.

Combined industrial quilting and embroidery machines generally offer higher stitch speeds and larger work areas. These features make it possible to complete more projects in less time. The ability to switch quickly between quilting and embroidery also allows businesses to meet tighter deadlines, ensuring greater throughput and improved customer satisfaction. This improved productivity is crucial for businesses that need to fulfill high-volume orders or meet demanding client specifications.

When selecting a combined quilting and embroidery machine, it’s important to assess your production needs. High-volume manufacturers will benefit from machines with high stitch-per-minute (SPM) rates and larger embroidery areas. A machine with greater speed can handle larger orders more efficiently, ensuring that the business remains competitive in a fast-paced environment.

Choosing a machine that can handle high production volumes without compromising quality is essential. For instance, advanced combined machines often come with features that allow them to switch between quilting and embroidery quickly, improving workflow without sacrificing stitch precision.

While speed is important, maintaining high-quality standards is paramount in the textile industry. Many combined industrial machines are equipped with advanced features like automatic tension control and stitch density adjustment. These features help ensure that both quilting and embroidery processes result in consistent, high-quality products. By minimizing errors and reducing the need for manual adjustments, these machines enhance overall quality control.

Some models also offer multiple needle options, which enable businesses to create more intricate designs and achieve finer detailing on embroidery projects. This flexibility ensures that businesses can cater to a wide range of customer needs, from simple quilts to complex, multi-colored embroidery designs.

For small businesses, space and cost are often major factors when choosing equipment. A combined machine offers the advantage of requiring less floor space than two separate machines, allowing smaller workshops to operate more efficiently. Additionally, businesses that operate within tight budgets may find that a combined industrial machine offers a more affordable solution than purchasing multiple separate machines.

For larger operations, however, it’s important to consider the scale of production. While combined machines are versatile, they may not be the best option for businesses with extremely high output demands. In these cases, purchasing specialized machines that can be used simultaneously for quilting and embroidery may still be the most efficient solution.

Industries such as fashion, home textiles, and custom promotional products can all benefit from combined quilting and embroidery machines. These machines can be adapted to various industry needs, whether creating custom quilts for retailers, producing embroidered uniforms, or crafting detailed home décor items. Businesses in niche markets, such as medical or automotive textiles, may require specific features, such as high precision and the ability to work with unique fabrics. A combined machine can often be customized to meet these demands.

Feature | Entry-Level Machine | Mid-Range Machine | High-End Machine |

Stitch Speed (SPM) | 600-800 SPM | 800-1,000 SPM | 1,000+ SPM |

Embroidery Area | 4" x 4" | 6" x 10" | 10" x 14" |

Max Layers Handled for Quilting | 2-3 layers | 3-4 layers | 4-6 layers |

Number of Needles for Embroidery | 1 | 1-2 | 2-6 |

Production Capacity (Units/Day) | 20-30 units | 30-50 units | 50+ units |

The latest combined quilting and embroidery machines are powered by cutting-edge software that integrates both functions seamlessly. Features such as automatic stitch length adjustment, thread tension control, and built-in design libraries streamline the production process and reduce the likelihood of errors. Software-driven automation allows businesses to focus on creativity and design, rather than the technical aspects of machine operation.

These machines are also designed to be compatible with digital design software, making it easier to create custom patterns and designs. This integration helps businesses stay competitive by enabling them to offer a wider variety of customized products to clients.

Feature | Traditional Machine | Combined Machine with Advanced Tech |

Automatic Thread Tension Control | No | Yes |

Stitch Design Software | Basic/Manual | Automated, with digital design integration |

Needle Threading Automation | Manual | Automatic |

Multi-Needle Capability | 1 | 2-6 needles |

Fabric Handling Technology | Limited | AI-powered, adaptive to fabric type |

Hooping System | Manual | Magnetic, automatic alignment |

As with many industrial machines, AI and robotics are playing a larger role in improving the functionality of combined quilting and embroidery machines. AI can optimize stitch placement and fabric handling, ensuring that the machine runs smoothly with minimal human intervention. Robotics also assist in tasks such as threading the machine, cutting threads, and even adjusting settings for different fabrics, which saves time and reduces the risk of mistakes.

In addition to improving performance, modern combined quilting and embroidery machines incorporate energy-saving technologies. Features such as efficient motors, automatic sleep modes, and reduced power consumption during idle times can significantly lower electricity costs. For businesses aiming to improve their sustainability, these energy-efficient machines offer a green solution that aligns with environmental goals while improving the bottom line.

The initial investment for a combined machine can be substantial, but it should be viewed as a long-term investment that will pay off in reduced operating costs and increased efficiency. The ability to perform both quilting and embroidery tasks on one machine minimizes downtime, which is a key consideration for businesses looking to maximize output.

Cost Category | Combined Machine | Separate Machines |

Initial Investment (USD) | $10,000 - $20,000 | $5,000 - $10,000 (each) |

Annual Maintenance Cost (USD) | $500 - $1,000 | $300 - $700 (each) |

Space Required (Square Feet) | 50-100 sq. ft. | 100-150 sq. ft. (total) |

Labor Costs (Operator) | 1 operator | 2 operators |

Energy Consumption (kWh/year) | 1,000 - 1,500 | 1,200 - 2,000 |

The return on investment (ROI) for a combined quilting and embroidery machine is usually realized within the first two years, depending on the scale of operations. By reducing the need for multiple machines, labor costs, and machine maintenance, businesses can recoup their investment relatively quickly.

For small and medium-sized enterprises (SMEs), financing options such as leasing or financing plans can help manage the upfront costs. Many manufacturers offer payment plans that allow businesses to invest in high-quality equipment without straining their cash flow.

A textile manufacturer was able to increase production by 30% by adopting a combined quilting and embroidery machine. This shift allowed the company to expand its product range, offering embroidered quilts and customized home décor items. The business was able to meet higher demand without needing additional space or staff, resulting in a significant boost to profitability.

A small custom gift business integrated a combined quilting and embroidery machine into their workflow, allowing them to produce personalized quilts at a faster pace. By reducing the time spent on setup and switching between machines, they were able to offer quicker turnaround times and attract more customers, increasing their sales by 40%.

Investing in a combined industrial quilting and embroidery machine offers significant advantages for businesses of all sizes. These machines improve efficiency, reduce costs, and expand product offerings. Whether you're a small business or a large-scale operation, their versatility and speed streamline production. Yiboda provides high-performance machines that enhance product quality and ensure long-term success, making them a valuable investment for businesses seeking to stay competitive in the textile industry.

A: A combined industrial quilting and embroidery machine is a versatile piece of equipment that handles both quilting and embroidery tasks seamlessly, allowing businesses to improve efficiency and expand product offerings with one machine.

A: Investing in a combined machine reduces operational costs, increases production speed, and enhances versatility, making it ideal for businesses looking to stay competitive in the textile industry.

A: A combined machine streamlines production by eliminating the need to switch between separate quilting and embroidery machines, saving time and reducing setup costs.

A: A combined machine offers cost savings by reducing equipment costs, maintenance, and space requirements, while improving productivity and output efficiency.