Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

Are you overwhelmed by the choices in industrial quilting embroidery machines? Selecting the right machine is crucial for your business success. In this article, we’ll explore key factors to consider, popular brands, and tips for making an informed decision. You’ll learn how to choose the best machine to meet your needs.

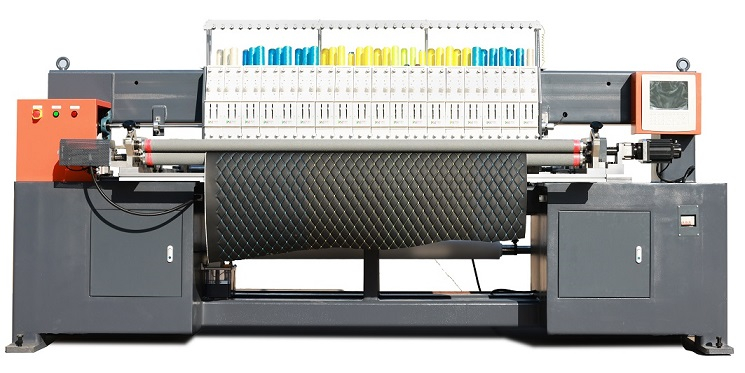

An industrial quilting embroidery machine is a specialized device designed for high-volume embroidery and quilting tasks. These machines combine advanced technology with robust construction to handle demanding workloads. Unlike domestic machines, industrial models are built for efficiency and durability, making them ideal for businesses.

Key Features of Industrial Machines:

● High Speed: Industrial machines operate at faster speeds, allowing for quicker project completion.

● Multiple Needles: Most models come equipped with multiple needles, enabling the use of various thread colors simultaneously.

● Larger Hoop Sizes: They accommodate larger embroidery areas, making it easier to work on bigger projects.

● Advanced Controls: Many have user-friendly interfaces with touchscreen controls for easy operation.

Feature | Industrial Machines | Domestic Machines |

Speed (Stitches per Minute) | 800-1000+ | 400-600 |

Needle Count | 6-12+ | 1-3 |

Embroidery Area | Up to 20" x 20" | Up to 8" x 8" |

Durability | Heavy-duty | Lightweight |

Investing in an industrial quilting embroidery machine can significantly enhance your business operations. These machines offer numerous benefits that can help you stay competitive in the market.

Benefits for Businesses:

1. Efficiency: The speed and capacity of industrial machines lead to faster production times. This efficiency can help meet tight deadlines and increase overall output.

2. Quality: Industrial machines provide consistent stitch quality, ensuring professional results that can elevate your brand’s reputation.

3. Scalability: As your business grows, these machines can adapt to increased demand without sacrificing performance.

Industries That Commonly Use These Machines:

● Textiles: Manufacturers use them for creating intricate designs on fabrics.

● Fashion: Designers rely on them for embellishing garments and accessories.

● Home Decor: Businesses producing quilts and decorative items benefit from their capabilities.

● Promotional Products: Companies embroider logos and branding on various items like hats, bags, and uniforms.

With these advantages, it's clear why many businesses opt for industrial quilting embroidery machines. They not only streamline operations but also enhance product quality, making them a worthy investment.

When selecting an industrial quilting embroidery machine, it's essential to assess your production needs accurately. Start by evaluating how much work you expect to handle daily. This assessment helps determine the machine's capacity, ensuring it meets your business demands.

Single-Head vs. Multi-Head Machines:

● Single-Head Machines: Ideal for small businesses or those just starting. They are versatile and cost-effective.

● Multi-Head Machines: Best for large-scale operations, allowing simultaneous production of multiple items.

Machine Type | Best For | Advantages |

Single-Head | Small-scale production | Lower cost, flexibility |

Multi-Head | Large-scale production | High output, efficiency |

For small-scale production, a single-head machine may suffice. However, if your business is growing and you anticipate higher volume, investing in a multi-head model can boost productivity.

The needle count on an industrial quilting embroidery machine directly impacts the quality of your embroidery work. A higher needle count allows for more intricate designs and faster production. For instance, machines with 6 to 12 needles enable you to use multiple thread colors without constant rethreading.

Adjustable stitch length is equally important. Different fabrics require varying stitch lengths for optimal results. For example, thicker materials might need longer stitches, while delicate fabrics benefit from shorter ones.

Understanding machine speed, measured in RPM (revolutions per minute), is crucial. Higher speeds lead to increased productivity. For example, Yiboda machines typically operate between 900 to 1000 RPM, which is competitive compared to other brands.

Brand | Speed (RPM) | Notes |

Yiboda | 900-1000 | High efficiency |

Competitor A | 800-900 | Standard performance |

Competitor B | 700-850 | Lower speed, less efficiency |

Choosing a machine with the right speed ensures you can meet deadlines without compromising quality.

The types of fabrics your machine can handle are vital. Industrial machines should be compatible with various materials, from lightweight fabrics to heavy-duty textiles. It's essential to ensure your chosen machine can adapt to different fabric thicknesses. This adaptability allows for greater versatility in your projects.

Modern industrial quilting embroidery machines come equipped with advanced control systems. Touch screens and intuitive software capabilities make operation smoother and more efficient. A user-friendly interface is essential, especially for beginners. Features like pattern editing and help functions can significantly enhance the user experience.

Automated features can transform your production process. For instance, thread detection systems automatically alert you when thread runs out, minimizing downtime. Many machines now offer smart features, enabling easier pattern editing and adjustments.

Yiboda stands out with its innovative automatic thread detection, making it easier for users to focus on creativity rather than troubleshooting. This technology can save time and improve overall efficiency, allowing you to produce high-quality work consistently.

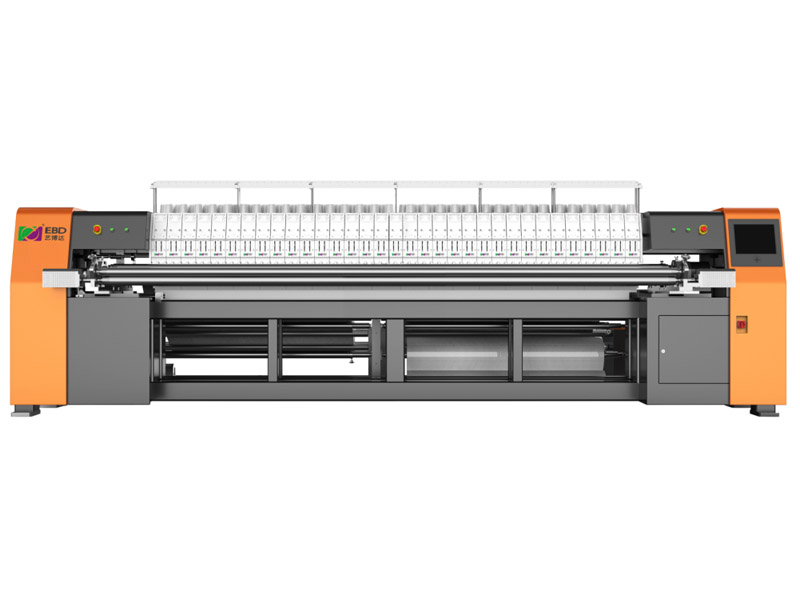

When it comes to selecting an industrial quilting embroidery machine, understanding the landscape of popular brands is crucial. Notable names like Yiboda, Tajima, and Richpeace dominate the market, each offering unique strengths and features.

● Yiboda: Known for its cost-effectiveness, Yiboda machines provide solid performance at a competitive price. They are ideal for small to medium-sized businesses looking for reliable functionality without breaking the bank.

● Tajima: This brand is synonymous with advanced features and high-quality construction. Tajima machines often come equipped with cutting-edge technology, making them suitable for larger operations that require precision and speed.

● Richpeace: Richpeace focuses on innovation, offering machines that integrate smart technology for enhanced user experience. They are popular among businesses that prioritize automation and efficiency.

Brand | Strengths | Weaknesses |

Yiboda | Cost-effective, reliable | Fewer advanced features |

Tajima | High quality, advanced technology | Higher price point |

Richpeace | Innovative, smart features | Can be complex for beginners |

When comparing these brands, consider your specific needs. If budget constraints are a concern, Yiboda may be the best choice. However, if you require advanced features and can invest more, Tajima or Richpeace could be worth the extra cost.

Finding the right balance between price and quality is essential when purchasing an industrial quilting embroidery machine. While it might be tempting to go for the cheapest option, it’s important to consider the long-term investment aspect.

Investing in a higher-quality machine often pays off in the long run. Machines made with durable components, such as high-grade bearings and reliable sensors, tend to last longer and perform better under heavy use. This durability can lead to less downtime and lower maintenance costs over time.

● Budgeting Wisely: Determine your budget but be open to spending a little more for better quality. A reliable machine can save you money in repairs and replacements.

● Long-Term Investment: Think about how often you plan to use the machine. For frequent use, investing in a quality model can enhance productivity and reduce wear and tear.

● Component Quality: Examine the materials used in the machine's construction. High-quality bearings and sensors are crucial for long-term functionality and reliability.

Factor | Low-Cost Option | High-Quality Option |

Initial Cost | Lower | Higher |

Durability | Shorter lifespan | Longer lifespan |

Maintenance Costs | Higher due to repairs | Lower due to reliability |

By carefully weighing these factors, you can make an informed decision that aligns with your business goals and operational needs. Remember, choosing the right industrial quilting embroidery machine is not just about the upfront cost; it’s about the value it brings to your business over time.

When investing in an industrial quilting embroidery machine, after-sales support is a critical factor that should not be overlooked. A reliable warranty and service agreement can save you from unexpected costs and downtime. Here’s what to consider:

● Warranty Coverage: Look for warranties that cover parts and labor. A comprehensive warranty provides peace of mind, ensuring you're protected against manufacturing defects or malfunctions.

● Service Agreements: Some brands offer extended service agreements that cover regular maintenance and repairs. These can be beneficial, especially for businesses that rely heavily on their machines.

● Customer Support Options: Effective customer support can make a significant difference. Check for available resources such as online manuals, video tutorials, and responsive customer service teams. Local service technicians are also a plus, as they can provide hands-on assistance when needed.

Brand | Warranty Length | Service Options | Customer Support |

Yiboda | 1 Year | Extended service plans available | Online support, local service |

Tajima | 2 Years | Comprehensive service agreements | 24/7 hotline, online resources |

Richpeace | 1 Year | Limited service options | Online forums, local technicians |

Comparing after-sales services among major brands helps you choose one that aligns with your needs. A brand with strong support can enhance your experience and ensure your machine remains operational.

To keep your industrial quilting embroidery machine running smoothly, regular maintenance is essential. Here are some practical tips to extend its lifespan:

● Routine Cleaning: Regularly clean the machine to remove dust and lint buildup. This practice prevents issues like thread jams and ensures smooth operation.

● Lubrication: Follow the manufacturer's recommendations for lubrication. Proper lubrication reduces wear on moving parts and enhances performance.

● Check for Wear and Tear: Regularly inspect components like needles and thread tension. Replacing worn-out parts promptly can prevent more significant issues down the line.

Even with proper maintenance, problems may arise. Here are some common issues and their solutions:

● Thread Breakage: This can occur due to poor-quality thread or incorrect tension. Ensure you use high-quality materials and adjust the tension settings as needed.

● Skipped Stitches: Often caused by a dull needle or incorrect needle type. Change the needle regularly and choose the right type for your fabric.

● Machine Jamming: This can happen due to lint buildup or improper threading. Always check threading paths and clean the machine frequently.

Using quality materials, such as threads and needles, is vital for preventing problems. High-quality threads reduce the likelihood of breakage, while the right needles ensure clean stitching. Investing in good materials not only enhances the quality of your work but also minimizes wear on your machine, contributing to its longevity.

Material Type | Quality Examples | Benefits |

Threads | Polyester, Rayon | Strong, less likely to break |

Needles | Organ, Schmetz | Sharp, designed for specific fabrics |

By following these maintenance tips and leveraging after-sales support, you can maximize the performance and lifespan of your industrial quilting embroidery machine.

Choosing the right industrial quilting embroidery machine requires careful consideration. A well-structured checklist can help streamline the decision-making process. Here are key points to consider before making a purchase:

● Budget Constraints: Determine your budget range early on. This helps narrow down your options and prevents overspending.

● Machine Features: Identify essential features such as stitch types, speed, and automation capabilities. Knowing what you need will guide your search.

● Brand Reputation: Research brands and their reputations in the industry. Look for reviews and testimonials from other users to gauge reliability.

When engaging with suppliers or manufacturers, it’s crucial to ask the right questions. Here are some inquiries to keep in mind:

● What is the warranty coverage for the machine?

● Are there service agreements available for maintenance?

● Can you provide references from other customers?

Customization can be a game-changer for your operations. Consider asking about:

● Voltage Options: Ensure the machine is compatible with your local power supply.

● Stitch Distance Adjustments: Inquire if the machine allows for customization in stitch distance to suit your specific projects.

Feature | Importance | Questions to Ask |

Budget | Keeps your selection focused | What is the total cost? |

Machine Features | Ensures it meets your needs | What features are included? |

Brand Reputation | Reflects reliability | Can you share customer reviews? |

Customization Options | Tailors to your requirements | What customization options are available? |

Understanding how others have successfully selected their machines can provide valuable insights. Here are some examples of businesses that made informed decisions:

● Fashion Apparel Manufacturer: A company specializing in high-end garments chose a Yiboda machine for its versatility. They highlighted the importance of stitch quality and speed, which significantly improved their production efficiency.

● Home Decor Business: Another business focused on custom quilts opted for a machine that allowed for various stitch patterns. They learned that investing in a machine with advanced features led to higher customer satisfaction and repeat orders.

From these case studies, several lessons emerge:

● Do Your Research: Thoroughly investigate options and gather as much information as possible before purchasing. This can save time and money later.

● Test Before You Buy: If possible, try out the machine to ensure it meets your expectations in terms of performance and ease of use.

● Consider Long-Term Needs: Think about how your business might grow in the future. Choosing a machine that can adapt to changing demands is a smart move.

Yiboda machines have proven successful across various industries, from fashion to home decor. Their ability to handle intricate designs while maintaining speed makes them a popular choice. Users report that these machines not only meet but often exceed their expectations, leading to increased productivity and creativity.

Industry | Success Story | Key Benefits |

Fashion | Improved production efficiency | High-quality stitching, faster turnaround |

Home Decor | Enhanced customer satisfaction | Versatile stitch patterns, reliability |

Promotional Items | Increased output for custom orders | Customization options, user-friendly design |

By creating a checklist and learning from real-world examples, you can confidently select the best industrial quilting embroidery machine for your needs.

In summary, selecting the best industrial quilting embroidery machine involves careful consideration of various factors. Key points include setting a budget, evaluating machine features, and researching brands.

Invest time in this process to ensure you make an informed decision.

Engage with the community or seek expert advice for additional support. Your choice can significantly impact your business success.

A: The average cost ranges from $5,000 to $20,000, depending on features and brand.

A: If you plan to produce large quantities or work on multiple designs simultaneously, a multi-head machine is beneficial.

A: Yes, industrial machines can handle home projects, offering efficiency and high-quality results.

A: Popular brands include Yiboda, Tajima, and Brother, known for their reliability and performance.

A: Inquire about warranty length, coverage details, and available maintenance service options.