Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

The textile industry is changing rapidly, especially in quilting. Leather and vinyl quilting has become more common, but it brings unique challenges.

In this article, we’ll explore these challenges and how specialized machinery solves them.

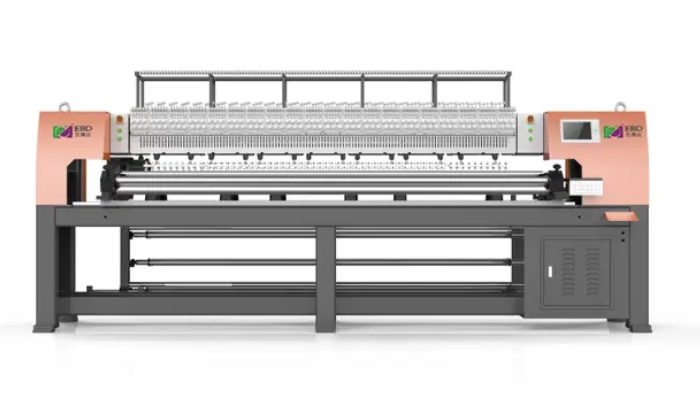

You’ll learn how the right equipment can help. Products from YIBODA are designed to meet these needs. Learn more about our products today.

Leather and vinyl present unique challenges compared to traditional quilting fabrics. These materials are thicker and less flexible, making them more difficult to handle on standard quilting machines. Leather and vinyl require specialized equipment to properly manipulate and quilt them, as they are tougher and resistant to manipulation. Unlike cotton or synthetic fabrics, which are more pliable, these materials need extra care to avoid damage during the quilting process.

Choosing the right needle and thread is critical when quilting on leather and vinyl. Using the wrong combination can result in skipped stitches, fabric tearing, or machine malfunctions. Leather and vinyl require heavy-duty needles, often with a specialized point, to pierce through the tough material. Additionally, the thread must be durable enough to withstand the stress of the quilting process without breaking or fraying. Ensuring the correct combination of needle and thread is vital to achieving consistent results.

The challenge with machine settings is that traditional quilting machines are often not built to handle the thickness and resistance of leather and vinyl. These materials require higher foot pressure to ensure they are held securely during the stitching process. Moreover, specialized feed dogs and the ability to adjust stitch length and width are crucial to avoid puckering or uneven stitching. Proper adjustments to the machine settings can help prevent these issues and improve the overall quality of the quilted product.

Traditional quilting machines are designed with fabrics in mind, and they often struggle with the dense, tough nature of leather and vinyl. Needle penetration can be inconsistent, leading to missed stitches or damage to the material. Because leather and vinyl are not as flexible as fabrics like cotton or polyester, the needle’s ability to penetrate these materials evenly can be hindered, affecting the final result. Additionally, the timing between the needle and hook may not be optimal for these tougher materials, leading to potential stitching issues.

Leather and vinyl require a strong and reliable feed mechanism capable of pushing heavy, non-slippery materials through the machine without causing damage or shifting. Standard feed dogs typically found on traditional quilting machines may not be sufficient for this task. As a result, fabric slippage or uneven stitching often occurs, especially when working with materials that are resistant to movement, such as vinyl. Specialized feed mechanisms, like walking feet or dual feed systems, are essential for ensuring even stitching and smooth material handling.

Feature | Ultrasonic Quilting Machines | Traditional Thread Quilting Machines |

Needle Penetration | Precise, no needle required | Can struggle with thick materials |

Feed Mechanism | Advanced, consistent | Standard feed dogs can slip |

Speed | Faster bonding and production | Slower stitching, especially manual |

Material Compatibility | Best for synthetic & non-woven fabrics | Works with a variety of materials |

Durability | Stronger, more consistent bond | Weaker, can wear over time due to thread |

Labor Requirements | Low (Automated) | High (Skilled labor required) |

Specialized quilting machines are equipped with heavy-duty needles that feature a wedge-shaped point. These needles are specifically designed for sewing through tough fabrics like leather and vinyl, ensuring smooth penetration. This minimizes the risk of skipped stitches or damage to the fabric, which is common with traditional needles.

Quilting machines designed for leather and vinyl often come with advanced feed systems, such as walking feet or dual feed mechanisms. These systems ensure that the materials are fed evenly through the machine, preventing slippage and ensuring smooth, consistent stitching. This is particularly important when handling thicker materials, as traditional feed systems often fail to handle their resistance effectively.

Another crucial feature of specialized quilting machines is the ability to adjust the foot pressure and feed dogs. This customization allows users to set the pressure according to the thickness of the leather or vinyl, ensuring that each stitch is even and smooth. It also prevents the material from being damaged by excessive pressure, which is a common concern when quilting on tougher fabrics.

Quilting on leather and vinyl requires machines that can handle heavy loads and still operate at high speeds. Machines with stronger motors are essential for tackling these tough materials efficiently. With the added benefit of faster stitching, the overall production process becomes quicker and more cost-effective, reducing downtime and increasing output.

When working with leather and vinyl, precision is vital. Specialized machines offer precise stitch control, ensuring that each stitch is consistent, regardless of the material's thickness. This is especially crucial for intricate stitching patterns, which are commonly used in applications like fashion and upholstery, where attention to detail is key.

Machines built for quilting leather and vinyl are designed to withstand the challenges of working with heavy-duty fabrics. These quilting machines are more durable and offer longer lifespans compared to standard machines. Investing in high-quality machinery ensures that businesses can handle large volumes of work without frequent machine breakdowns, making them a smart, long-term investment.

Feature | Importance | Benefit |

Heavy-Duty Needles | Ensures penetration through thick, tough materials | Prevents needle breakage and stitching errors |

Adjustable Foot Pressure | Customizable for different material thicknesses | Achieves even stitching and prevents damage |

Dual Feed Mechanism | Helps feed tough materials evenly | Ensures smooth, consistent stitching |

Stronger Motors | Required for high-speed and heavy-duty operations | Increases efficiency and production speed |

High Precision Stitch Control | Essential for consistent, high-quality results | Minimizes errors and ensures clean, durable stitching |

While specialized quilting machines for leather and vinyl come with a higher upfront cost, they can save businesses money in the long run. These machines reduce the need for manual labor and minimize material waste, leading to lower operating costs over time.

For smaller businesses, investing in high-quality quilting machines may seem daunting, but there are cost-effective solutions available. Many models offer scalability, allowing smaller operations to increase production without making a significant financial investment.

Machine Type | Initial Investment | Long-Term Savings | Labor Costs | Material Costs |

Ultrasonic Quilting Machines | High | Significant savings over time | Low (Automated) | Lower (No thread) |

Traditional Thread Quilting Machines | Low to Medium | Higher overall production cost | High (Manual) | Higher (Thread needed) |

Properly preparing leather and vinyl before quilting is essential for achieving optimal results. This includes cleaning, cutting, and conditioning the material to ensure smooth handling. Pre-washing (where applicable) and pressing the fabric can help avoid issues during stitching. Taking the time to prepare the materials correctly will prevent unnecessary delays and ensure clean, even stitching when quilting on these challenging surfaces.

When quilting on leather or vinyl, it is crucial to adjust machine settings for optimal results. The stitch length should be set appropriately to prevent stitches from becoming too tight or too loose. Additionally, foot pressure must be adjusted to ensure that the material is fed evenly without slipping or causing uneven stitching. Needle tension is also important; it should be set to avoid puckering or stretching of the leather or vinyl. Fine-tuning these settings ensures that the stitching is smooth and consistent, preventing fabric damage.

Before starting full production, always conduct test runs on scrap material. This allows you to adjust settings and make any necessary changes to your machine. Testing helps prevent costly mistakes and ensures a smoother process by allowing you to fine-tune the machine’s performance. By checking the results on scrap pieces, you can ensure that the final product meets quality standards and avoid issues with the actual production.

With ongoing advancements in technology, future quilting machines for leather and vinyl are expected to be even more efficient. The integration of artificial intelligence (AI) and automated systems will allow machines to adjust settings automatically based on the fabric type being used. This will improve speed and precision, providing better results for manufacturers working with leather and vinyl. AI-based machines could also learn from previous projects to optimize settings for various materials, increasing overall productivity.

Automated quilting machines are becoming increasingly common in the industry. These machines help improve productivity by reducing human error and providing more consistent results. Real-time feedback through smart technology allows for continuous optimization of machine settings. Automated systems can track production patterns and make adjustments based on material behavior, reducing waste and improving efficiency. This shift to automation is shaping the future of quilting, especially in high-volume production environments.

As sustainability becomes a growing concern in the textile industry, new eco-friendly quilting machines are being developed. These machines are designed to use less energy, reduce waste, and support environmentally friendly manufacturing practices. Energy-efficient motors and waste-reducing features are becoming standard in new quilting machine designs. These innovations help businesses meet environmental goals, reduce their carbon footprint, and appeal to eco-conscious consumers. As eco-friendly technology continues to evolve, quilting machines will become even more aligned with sustainable practices.

Quilting on leather and vinyl presents unique challenges, but specialized machinery can overcome them. Machines with heavy-duty needles, advanced feed systems, and precise control offer effective solutions. As technology advances, these machines will become more efficient, helping businesses improve productivity and reduce costs. Products from YIBODA are designed to meet these needs, providing value and efficiency for manufacturers.

A: Quilting on leather and vinyl presents challenges such as needle penetration issues, material thickness, and the need for specialized feed systems to handle tough fabrics.

A: Specialized quilting machines, equipped with heavy-duty needles and advanced feed systems, provide consistent stitching and improved efficiency when working with leather and vinyl.

A: Traditional quilting machines lack the necessary feed mechanisms and needle strength to handle the tough, non-slippery nature of leather and vinyl effectively.

A: By investing in specialized quilting machines from YIBODA, businesses can reduce labor and material costs while improving production speed and consistency.