Views: 0 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

The textile industry is changing rapidly. Ultrasonic quilting is replacing traditional thread quilting. It offers speed, efficiency, and precision. Traditional quilting is still valued for its intricate designs and versatility.

In this article, we will compare the two methods. We’ll discuss their benefits, challenges, and future implications. You will learn how each method impacts production.Products from Yiboda help manufacturers stay competitive in this changing industry.

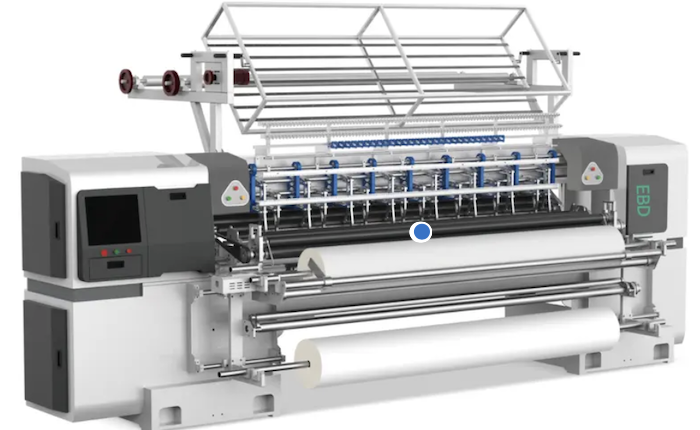

Ultrasonic quilting uses high-frequency sound waves to bond fabric layers together. The sound waves generate heat, which melts the fabric at specific points, creating a secure bond. This method works best with synthetic and non-woven materials, making it a fast and efficient alternative to traditional quilting methods. Ultrasonic quilting machines are equipped with advanced features, ensuring precise and consistent results. These machines move through fabric layers with ease, ensuring even and flawless bonding, even for large production volumes.

Ultrasonic quilting stands out due to its efficiency and consistency. The process is much faster than traditional methods, drastically reducing production times. Automation in ultrasonic quilting lowers labor costs, as fewer workers are needed. Since no thread is used, material expenses are also reduced. Additionally, the bonding is highly consistent across fabrics, eliminating human error that can arise in traditional quilting. These advantages make ultrasonic quilting ideal for high-volume manufacturing operations, especially those in industries demanding efficiency and consistent product quality.

Benefit | Ultrasonic Quilting | Traditional Thread Quilting |

Speed | Faster bonding, quick production | Slower due to manual or machine stitching |

Cost | Reduced material costs, lower labor | Higher due to thread and skilled labor |

Consistency | Uniform results across products | Variation in stitch quality |

Durability | Stronger, more consistent bond | Can wear out over time due to thread fraying |

Traditional thread quilting involves stitching multiple layers of fabric together using thread. This age-old method is valued for its ability to produce intricate and decorative designs. It's particularly useful for high-end applications where the detailed stitching adds considerable value to the finished product. Traditional quilting is also highly versatile and can be used on a wide range of materials, making it suitable for custom, intricate patterns.

Traditional thread quilting is known for its creativity and flexibility. The method allows for intricate stitching patterns, which ultrasonic quilting cannot replicate. This makes traditional quilting ideal for custom designs or artistic elements, particularly in high-end fashion or textile products. Furthermore, thread quilting is compatible with various types of fabrics, including heavier materials like cotton and denim, which are challenging for ultrasonic quilting to bond effectively. Despite the rise of ultrasonic quilting, many industries still prefer traditional thread quilting for its craftsmanship and ability to handle different materials and designs.

Advantage | Ultrasonic Quilting | Traditional Thread Quilting |

Design Flexibility | Limited for intricate designs | Allows for complex and detailed patterns |

Material Compatibility | Best with synthetic/non-woven | Works with various materials, including heavy fabrics |

Craftsmanship | Automated, no manual involvement | Manual or machine, offering a personal touch |

Ultrasonic quilting provides a competitive advantage in terms of speed. It bonds fabric layers nearly instantly, enabling manufacturers to produce products faster and meet high-volume demands. In contrast, traditional thread quilting is slower, especially when it involves intricate stitching or manual operations. The efficiency of ultrasonic quilting allows for faster turnarounds, which is crucial in industries where quick production cycles are needed.

Ultrasonic quilting reduces labor costs due to its automated nature. Fewer workers are needed to operate the machinery, and the absence of thread further reduces material costs. Conversely, traditional thread quilting requires skilled labor to ensure quality stitching. Additionally, the use of thread adds to material expenses, making thread quilting more expensive in terms of both labor and materials.

Aspect | Ultrasonic Quilting | Traditional Thread Quilting |

Labor Requirement | Less labor-intensive due to automation | Requires skilled labor for stitching |

Thread Usage | No thread required | Significant thread usage |

Production Cost | Lower over time | Higher due to labor and material costs |

Ultrasonic quilting offers more consistent and durable results. The bond formed by ultrasonic waves is stronger, and because it doesn't rely on thread, it’s less prone to wear over time. Thread quilting, while still durable, can exhibit inconsistencies in stitch quality depending on the operator’s skill. Additionally, the thread itself can weaken over time, which can lead to less durable seams.

Ultrasonic quilting is becoming increasingly popular in the fashion industry. Its ability to quickly bond lightweight fabrics gives designers the ability to create modern, sleek garments. As trends move quickly, this method allows for fast adaptation and production. The flexibility in design, with no need for thread, makes ultrasonic quilting ideal for mass production, while still offering a high-quality finish for high-fashion items.

In home décor, ultrasonic quilting is an excellent solution for creating durable and visually appealing products such as bedspreads, pillow covers, and mattress protectors. The speed and strength of ultrasonic quilting make it suitable for large-scale production. In upholstery, the technique offers clean and precise seams, removing the need for traditional stitching. This results in a modern and durable finish, ideal for the evolving demands of interior design.

Ultrasonic quilting is particularly beneficial in the medical textile sector. It provides strong, reliable seams for products like surgical gowns and medical drapes. The precision and durability offered by ultrasonic quilting make it a preferred choice for high-performance applications. These include technical textiles, where safety and consistency are paramount, and where traditional quilting may not be suitable due to the material limitations.

One of the main barriers to adopting ultrasonic quilting is the initial cost of the machinery. Ultrasonic quilting machines are typically more expensive than traditional sewing machines, and this can be a significant hurdle for smaller businesses or those with limited capital. For companies operating on tight budgets, the high upfront cost can be daunting.

However, it is important to note that the long-term savings resulting from reduced labor and material costs can offset the initial investment. As ultrasonic quilting improves production efficiency, the savings in labor costs and material waste make it an attractive option for businesses that can afford the initial outlay. Over time, these savings can significantly lower overall production costs.

Ultrasonic quilting works best with synthetic and non-woven fabrics, which are bonded together using high-frequency sound waves. This makes it ideal for many applications, such as fashion, home décor, and medical textiles. However, it limits the variety of materials that can be used compared to traditional thread quilting, which works with almost any fabric type, including cotton, wool, and denim.

For businesses that need to work with heavier, natural fabrics, traditional thread quilting remains a more versatile choice. This limitation can make ultrasonic quilting less suitable for industries that require diverse textile types, such as the heavy-duty upholstery or outdoor apparel sectors.

While ultrasonic quilting has proven to be highly effective for certain applications, businesses that deal with natural or thicker fabrics may face challenges. The lack of flexibility with material choices can make it less appealing for industries that need versatile equipment capable of working with various fabrics. As a result, manufacturers in such industries may prefer to stick with traditional thread quilting for the time being.

As ultrasonic quilting technology continues to evolve, future machines will likely become even more efficient and versatile. Advances in automation and artificial intelligence (AI) will enhance the capabilities of ultrasonic quilting machines. For instance, AI integration could enable machines to automatically adjust their settings based on the type of fabric being used and the complexity of the design. This level of flexibility could drastically reduce the need for manual adjustments, streamlining the production process even further.

Moreover, machine learning could allow ultrasonic quilting systems to “learn” from previous projects, optimizing their settings for the best possible output. These innovations would improve production speeds, reduce the risk of errors, and ensure even higher-quality results, positioning ultrasonic quilting as a highly competitive option in the future textile manufacturing landscape.

As ultrasonic quilting technology becomes more affordable, its adoption is expected to rise across various industries. The cost of ultrasonic quilting machines has already been decreasing steadily, and as this trend continues, it is anticipated that more manufacturers will adopt the technology for its efficiency and eco-friendly benefits.

Sectors such as fashion, automotive, and medical textiles are likely to benefit from the speed, consistency, and sustainability offered by ultrasonic quilting. This method reduces material waste and energy consumption, making it a suitable option for companies seeking to meet sustainability goals. Ultrasonic quilting can contribute to lower environmental impact while maintaining high-quality production standards. With increasing demand for eco-friendly manufacturing processes, ultrasonic quilting is poised to become an industry standard.

Ultrasonic quilting offers significant advantages over traditional thread quilting, especially in speed, efficiency, and consistency. While it requires a higher initial investment and has material limitations, it provides long-term benefits like reduced labor costs and better durability. As technology advances, ultrasonic quilting is set to revolutionize textile manufacturing. It helps businesses increase production efficiency and meet the growing demand for sustainable, high-performance textiles. Products from Yiboda are designed to offer innovative solutions, helping manufacturers optimize their operations.

A: The primary advantage of ultrasonic quilting is its speed. Ultrasonic quilting bonds fabric layers quickly, reducing production time compared to traditional stitching methods.

A: No, ultrasonic quilting is most effective with synthetic and non-woven fabrics. It is less compatible with heavier, natural fabrics like cotton or wool, which are better suited for thread quilting.

A: In the long term, ultrasonic quilting can be more cost-effective due to lower labor costs and the elimination of thread. However, the initial investment in ultrasonic quilting machines can be high.

A: Ultrasonic quilting is set to revolutionize the textile industry by providing faster production, reducing material waste, and meeting the demand for eco-friendly manufacturing practices, especially in high-volume production environments.